Interdisciplinary Research Leads to Next-Generation Dressing for Chronic Non-healing Wounds

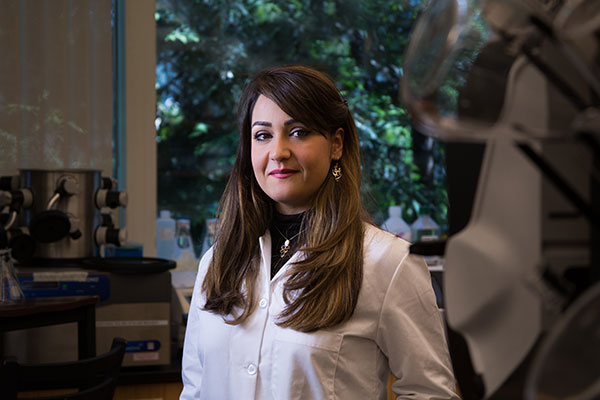

Inspired by a passion for translating research into products that can improve healthcare, Assistant Professor of Chemical Engineering Nasim Annabi and her team at Northeastern University undertook an interdisciplinary approach to solve the problem of chronic wounds. This led to the development of the first elastic and adhesive wound dressing that has adhesive, antimicrobial, and regenerative properties. Research findings of this next-generation wound dressing for chronic non-healing wounds have been published in the prestigious journal, Biomaterials.

More than 2% of the U.S. population suffer from chronic wounds, which represents an estimated $20 billion in healthcare-related costs each year. Chronic wounds take longer than four weeks to heal and can be caused by diabetes, circulatory issues, pressure ulcers, or burns. Conventional therapies such as sutures, staples, or skin grafts present a high probability of infection and do not promote skin regeneration. Furthermore, a bacterial infection can severely prolong the healing process and lead to sepsis, or even death. In this regard, the overall misuse of antibiotics has led to an escalating drug resistance in microorganisms, which in turn leads to longer hospital stays, higher medical costs, and increased mortality.

With her research expertise in engineering tissue adhesives and elastomeric biomaterials, Annabi realized the urgency to develop a multifunctional biomaterial that would not only replicate the properties of the native skin, but also address the risk of injection, minimize the need for suturing, control bleeding, and promote skin repair. After a year of research at Northeastern’s Biomaterials Innovation and Tissue Engineering Lab, Annabi’s team engineered a new class of highly adhesive and antimicrobial hydrogels, which are comprised of two naturally occurring proteins, gelatin, and tropoelastin.

Instead of a traditional approach using UV light for photopolymerization, the team employed a system based on visible light to form an elastic, adhesive, and antimicrobial barrier on the wound area. Their strategy greatly minimizes the risk of infection through an approach that is impervious to the development of antibiotic resistance. In addition, the adhesive provides breathability to the wound, and can be naturally degraded by the body to be replaced with new healthy tissue.

According to Dr. Roberto Portillo, a chemical engineering postdoc at the Annabi lab, the hydrogel precursor can be sprayed on wounds of any size and shape, and its physical properties can be finely tuned based on the final application. Assistant Professor Nasim Annabi said, “This next-generation dressing for chronic non-healing wounds has the potential for clinical translation as a suture-free approach for immediate sealing of wounds and long-term healing due to the intrinsic properties of its components. In addition, the engineered adhesives have potential to be used for sealing and repair of other soft tissues such as lung, heart, and blood vessels.”